Extending the Steaming Season Through David Thompson’s “Quick Winterization”

Earl Morse- Steam Happens #6

I did some cruising during the foliage season this fall. I have an insulated, heated barn and I set the thermostat to 40F to keep the boat from freezing. During my last cruise in October the sugar maples were in full color and the shoreline was an artist’s gaudiest dream. I loved it! No other boats on the lake, the exhaust steam and whistle showing full cloud-plumes in the cool weather, and the quiet and peace of New England autumn. I enjoyed this fall’s cruising so much that I realized that I would really love to be able to take advantage of an extended cruising season.

Dave Thompson, organizer and founder of the Lee's Mills Meet has the ability to be the last boat out in the fall and the first boat in in the spring. He has adapted his boat for "Quick Winterization." That means he can winterize and de-winterize in about ten minutes. So his boat is in no danger of freezing even though he keeps it outdoors on the trailer. Here he is in his winter coat on December 20th, standing beside the Radio Flyer ready to roll to the boat ramp.

How can he do it? Here’s what you need to add to your piping:

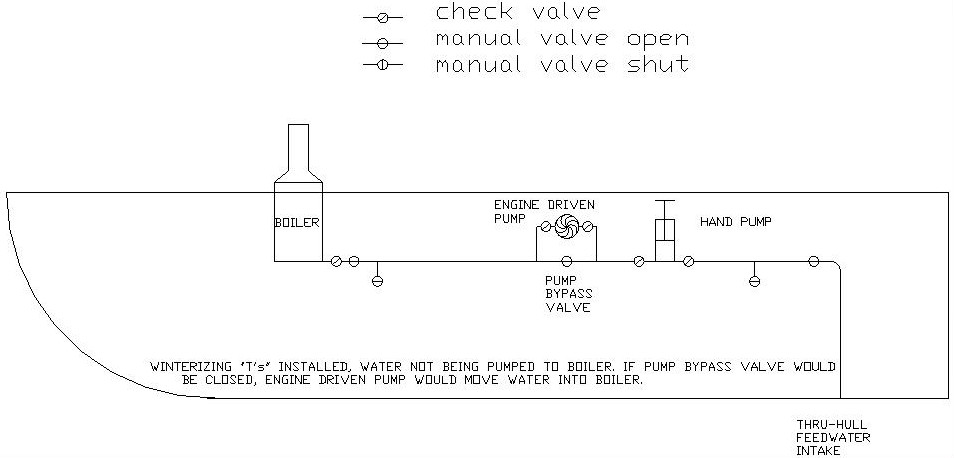

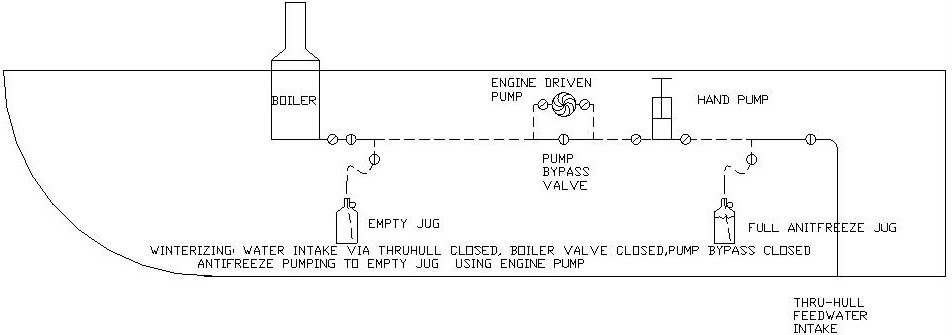

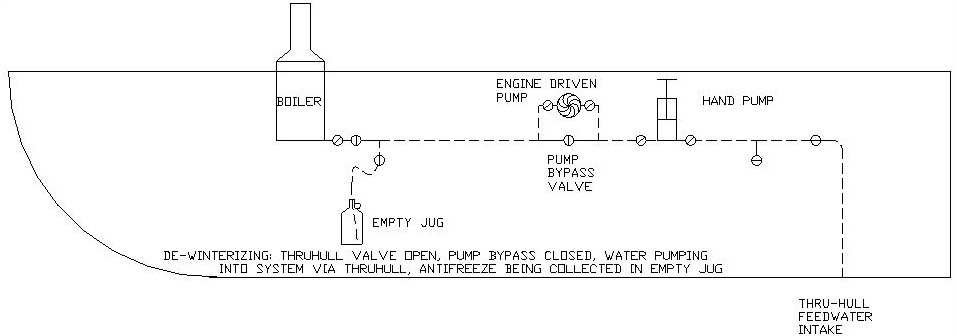

The diagrams below are highly simplified for the sake of clarity. Condensers, hotwells air pumps, injectors etc. have been omitted to help show the general nature of the process as simply as possible. You will probably have to do a bit of thinking to adapt this procedure to your boat.

Two-foot long lengths of hose are fitted to each of these “T’s” when used for this purpose.

How to quickly winterize and de-winterize your boat for cool weather steaming.

To quick winterize your boat:

1. Toward the end of your cruise, blow down your boiler at least twice until clear water flows from the boiler mud drums. It is crucial that the boiler is clear of residue, so it’s a good idea to do a couple partial blowdowns as you near the dock at the end of your run.

2. Wait till the fire has diminished and the grate is about 1/3 covered with glowing coals. No significant flame should be visible. Allow pressure to drop to your minimal headway pressure 20-30 psi, no more than 40 psi.

3. Uncap the sidearm of the “T” closest to the boiler and fit the hose adapter and 2 foot hose to this sidearm. Insert hose into an empty one-gallon antifreeze bottle.

4. Place a bottle of RV (non-toxic) antifreeze on the sidearm of the “T” next to the water intake. Insert this hose into the full antifreeze bottle.

5. Close the feedwater intake valve, the one next to your water intake thru-hull. If you have them, also shut the hotwell valve and makeup water tank valve (empty the makeup water tank first).

6. Open the valve to the antifreeze bottle on the T sidearm closest to the water intake.

7. Open the valve to the empty bottle on the T closest to the boiler.

8. Close the mechanical water pump bypass valve.

9. Slowly open your throttle valve and allow engine crank the water pump to slowly move antifreeze throughout the system. Continue until the antifreeze clearly is flowing into the empty receiver bottle. Once the antifreeze is visibly flowing into the empty receiver bottle, move manual pump handle a few times to replace the water with antifreeze. Also open the pump bypass valve for a few seconds to circulate the antifreeze through the bypass. If you have an injector, open the valve until you see antifreeze coming out the overflow.

Once you have loaded the plumbing with antifreeze, open the blowdown valve(s) and let the boiler go dry. The remaining firebox heat should be sufficient to dry the boiler internally. Leave the fire door open, shut the draft and/or ashpit door and let the boiler cool slowly

Managing this procedure depends on knowing your homewater’s mud drum solids accumulation rate and developing a blowdown procedure to routinely clear your mud drums. To establish this procedure, you need to monitor your blowdowns and occasionally monitor the mud drum internals once the boiler has cooled to make sure there is no moist residue. The residue in the dried mud drums should be minimal, dry and powdery to the touch. If there is some moisture in the mud drum after the boiler is cooled, you may want to put a small newspaper fire under the boiler and/or use a shop vac or hair drier to remove the dampness once you get home. If there was any trace of boiler moisture, the next time you “quick winterize” try leaving a few more glowing embers on the grate. With monitoring and practice, you will soon determine your best drying procedure.

To de-winterize:

I’ve just added the requisite hardware to my system. “Ice Out” is usually mid-April. I’ll get the boat in the water a lot earlier this year AND I don’t have to heat my barn in order to keep my system clear of ice. Since we have a lot of winter power failures here in the back woods, Antifreezing will save me a lot of worry and hustle when the lights go out in Maine!

I’ve included a few pictures of David’s “T’s and mine. Dave is a strict adherent to the KISS principle, so his “T’s” are simple and very functional. The intake “T” is simply a T flare fitting with a cap on the sidearm, no globe valve. He removes the cap and screws on a short length of copper with a rubber tube fit to the end.

The next photo shows Dave’s boiler “T.” He hasn’t attached the hose and empty bottle at this point. His hand is on the globe valve. You can see the hose and antifreeze bottle in the background.

My “T’s” are more complex because I wanted to be able to attach a garden hose to my water intake. I shut the thru-hull intake (left handle in photo below), attach a garden hose to the “T” side arm and open the side arm globe valve (right handle). Here you see a half full bottle of antifreeze ready to be drawn into the plumbing.

Below you can see the antifreeze flowing into the receiver jug. It has now permeated the entire plumbing.

You can download a couple of movies of the process. Unfortunately, I got my plumbing job finished in January so the boat is in the barn and the engine is running on compressed air. So it's a bit noisy.

These are very large (3 meg) files. Don't attempt to download unless you have a broadband connection or way too much time on your hands.

Click here to download and view the first movie.

Click here to download and view the second movie